edible hydrophobic coating

Wax was the first coating used in fruits specifically in citrus fruits. This ensures that the compounds will be well-dispersed over the surface of the treated food 25.

13 Summary Of Different Applications Of Edible Coatings And Films In Download Table

Edible coatings are discussed for meats cheese fruit and vegetables confectionery bakery goods and fast food.

. Petroleum-based waxes such as paraffin and polyethylene wax. An edible coating can also be used as an effective carrier of many functional ingredients including antimicrobial agents antioxidants flavorings and colorants Chen 1995. Composite edible coatings based on hydroxypropyl methylcellulose HPMC as a polymeric phase and oleic acid OA or beeswax BW as a hydrophobic phase were formulated with different food additives as antifungal ingredients.

We used FDA-approved edible materials to fabricate superhydrophobic coatings in a simple low cost scalable single step process. Disclosed is an edible coating a food product coated with the coating and the method for manufacturing the food product. Foods such as minimally processed products are especially.

In this work a thermo-resistant edible super-hydrophobic coating has been fabricated using beeswax. The nature of the gluten has significant. Droplets hitting this kind of coating can fully rebound.

Peng Wang Xueren Qian and Jing Shen Biowaxes including carnauba wax and beeswax are edible and renewable. Our coatings display high. The edible coating plays an important role as a gas barrier so it causes anaerobic respiration in fruits and vegetables which results in causing a delay in the ripening process.

A very wide range of compounds is available for increasing the hydrophobicity of lipid-based edible films and coatings. Generally speaking superhydrophobic coatings are made from composite materials where one component provides the roughness and the other provides low. We used FDA-approved edible materials to fabricate superhydrophobic coatings in a simple low cost scalable single step process.

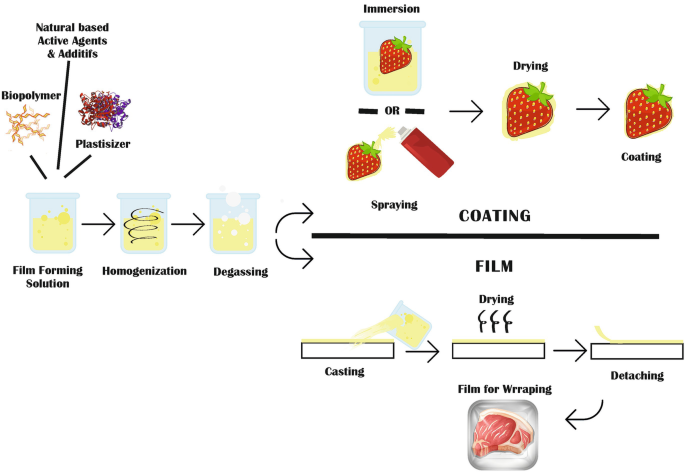

Gelatin is a hydrophobic protein usually found in wheat which is also a globular protein and also used in some edible coatingsfilms due to its low cost and availability. Edible films are made by casting and the extrusion process and coating of the edible solution are done by dipping and spraying. Professor Ilker Bayer from the Italian Institute of Technology in Genova Italy address these issues by forming hydrophobic and superhydrophobic smart coatings based on bees wax and water.

Gestión en línea. Fruits and vegetables are coated in nature by a natural waxy coating called cuticle consisting of a layer of fatty acid-related substances such as waxes and resins with low permeability to water Baldwin 1994. This protective layer acts as a barrier between the food and external environment and thus delay the ripening and spoilage process.

Hydrophobic substances potentially used in this way include natural waxes such as carnauba wax candelilla wax rice bran wax and beeswax. The coating matrix results in. Gelatin coatings usually depict good transparency mechanical and barrier properties and can be manufactured via an extrusion or casting process.

Edible super-hydrophobic coatings have attracted great attentions as they can avoid the waste of liquid foods such as honey and milk adhered to the inside of containers. Edible films and coatings may be defined as protective layers created around food surface by applying solutions made from edible polymers like polysaccharides proteins lipids or their combinations. It is free from waxes and has been designed with optimal hydrophilic-hydrophobic balance to achieve good water vapor resistance and barrier properties.

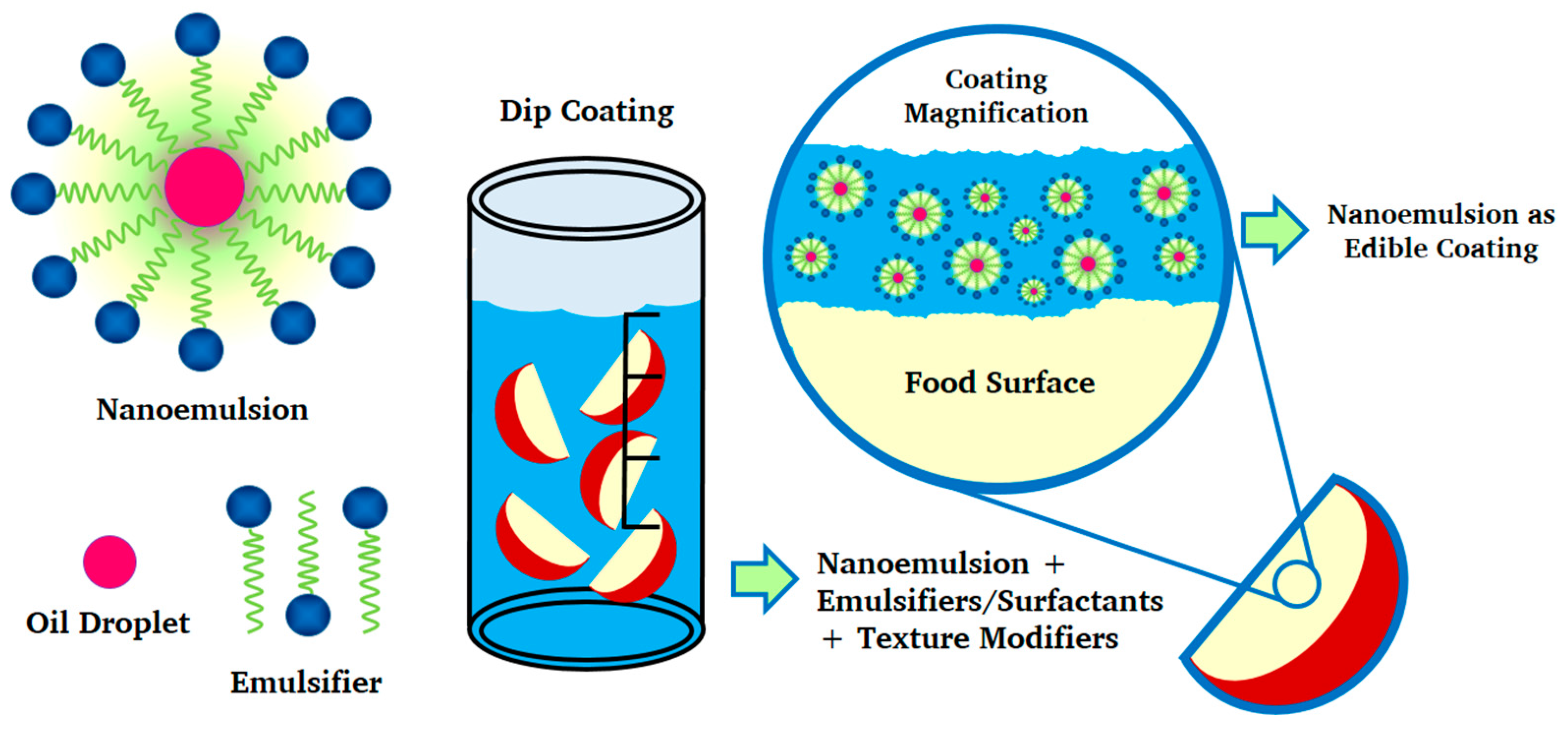

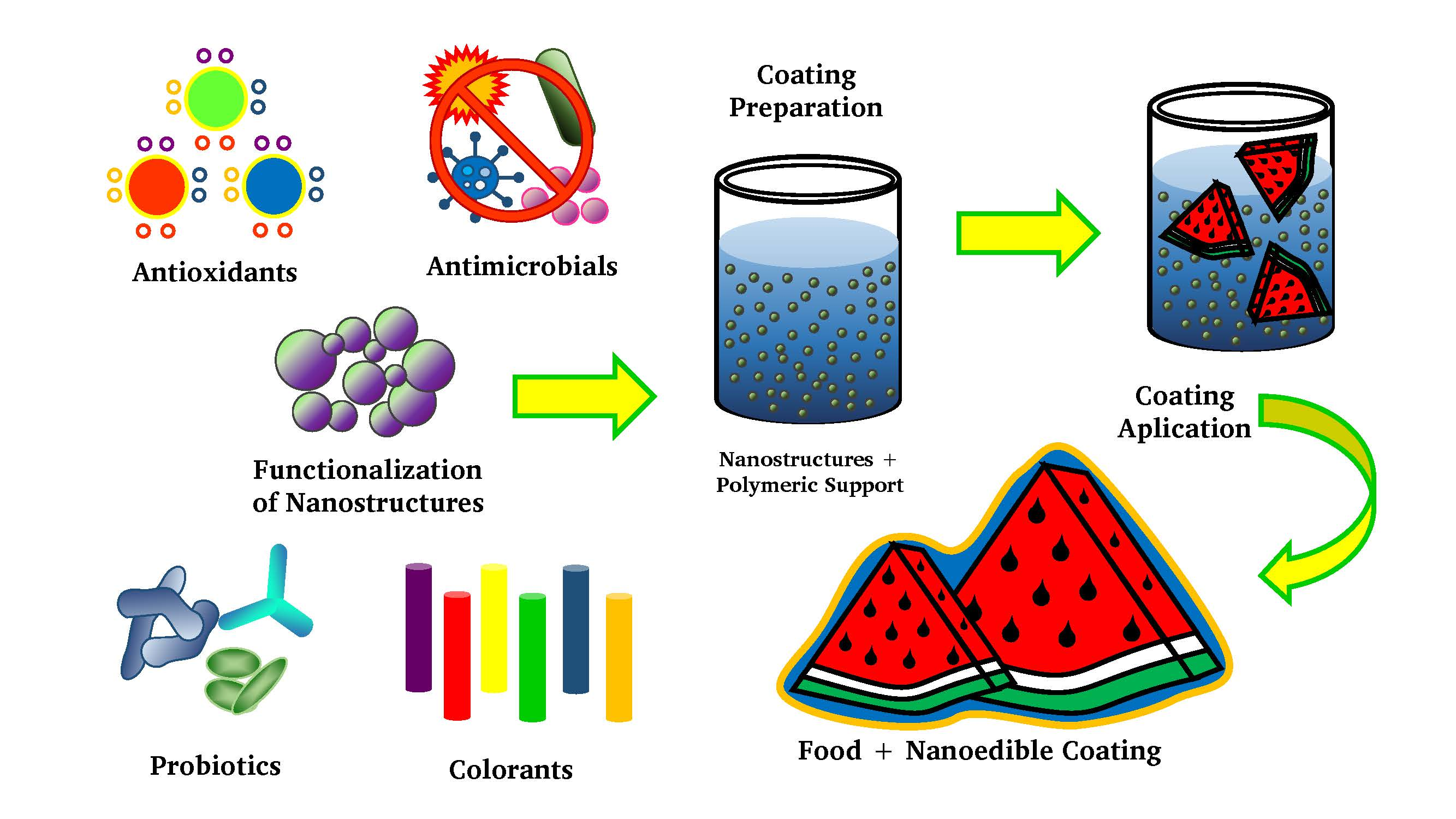

Edible coatings are packing systems that are highly-predisposed to incorporate polymeric nanoparticles because of the chemical compatibility of the nanoparticle matrix or shell and the composition of the edible coating support. There are several categories of antimicrobials that can potentially be incorporated into edible coatings. They are created entirely from food-grade ingredients such as proteins polysaccharides or lipids and are usually 5 nm thick.

The food product having the coating is. In the last few years a great deal of interest has been given over to applying edible coatings to highly perishable food products. Once dispersed in a polar solvent these natural materials could be easily converted into nontoxic roll-off and superhydrophobic.

It is made from superhydrophobic ultrahydrophobicity materials. HPMCOA coatings containing 2 wv sodium benzoate SB 1 ammonium carbonate AC 1 potassium carbonate PC 1. Superhydrophobic Coatings with Edible Biowaxes for Reducing or Eliminating Liquid Residues of Foods and Drinks in Containers.

In contrast the edible coating forming solution is applied to the food product. In other words the team has created an effective phase change material PCM from natural materials. Even at high concentrations our coatings are.

Edible coatings could provide a barrier for moisture and gas or act as a vehicle to deliver colors flavors antioxidants. 1 organic acids namely lactic acetic propionic benzoic sorbic 2 fatty acid esters such as glyceryl monolaurate 3 polypeptides such as peroxidase lysozyme lactoferrin nisin and 4 plant essential oils such as cinnamon. The significant difference is that in edible film solid edible laminate is wrapped around the food products.

The coating comprises a first layer comprising first edible oil and a second layer comprising a hydrophobic edible particle wherein the hydrophobic edible particle has a diameter from 20 nm to 500 microns. However the poor thermal stabilities of edible super-hydrophobic coatings restrict their applications. Texcoat FV Pro is a proprietary triglyceride based edible coating.

Our coatings display high contact angles and low roll off angles for a variety of liquid products consumed daily and facilitate easy removal of liquids from food containers with virtually no residue. Disclosed are an edible coating a food product coated with the coating and the method for manufacturing the food product. A superhydrophobic coating is a thin surface layer that repels water.

In addition these coatings can store latent heat.

Most Utilized Materials For Protein Based Edible Films And Coatings Download Scientific Diagram

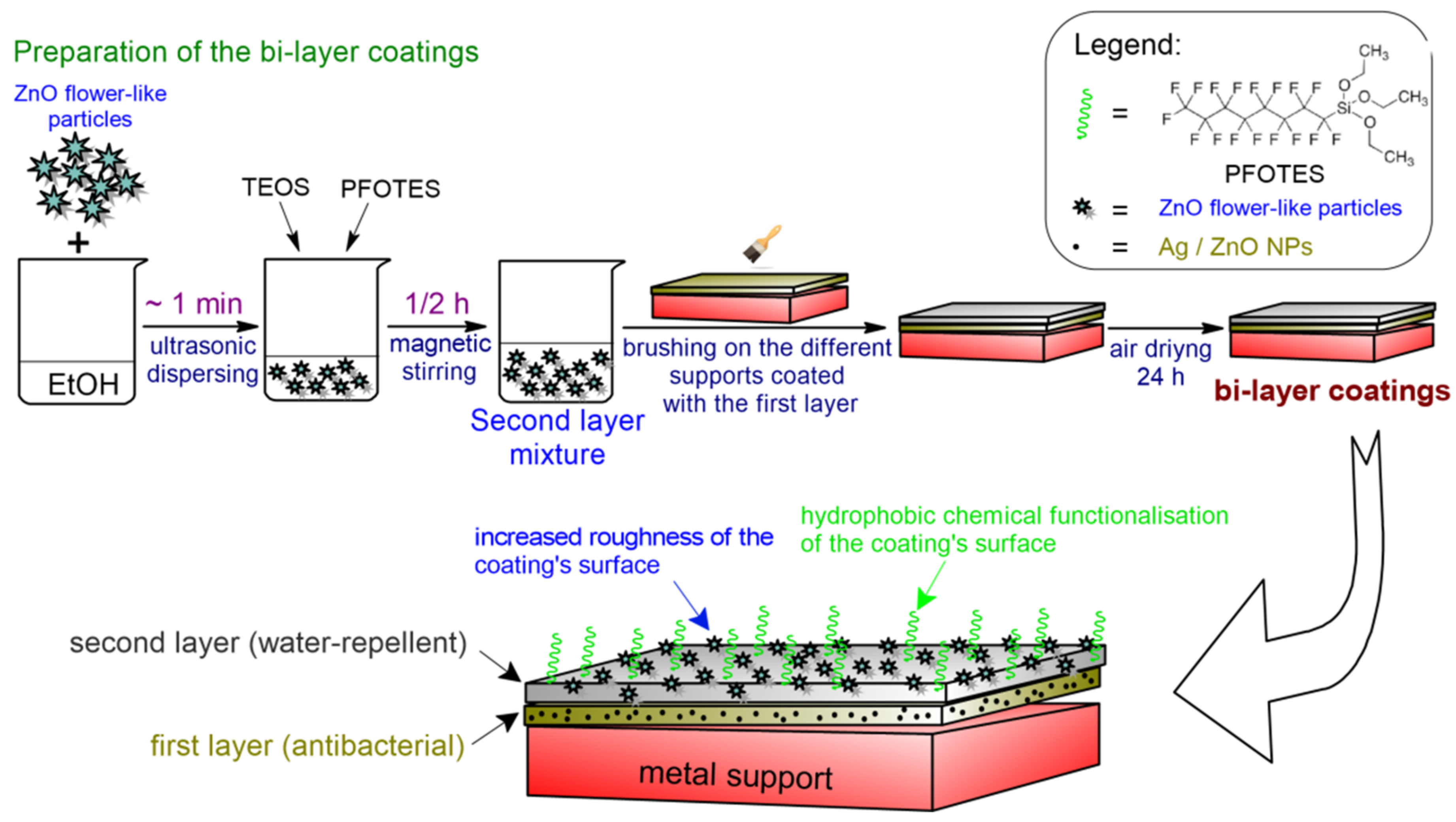

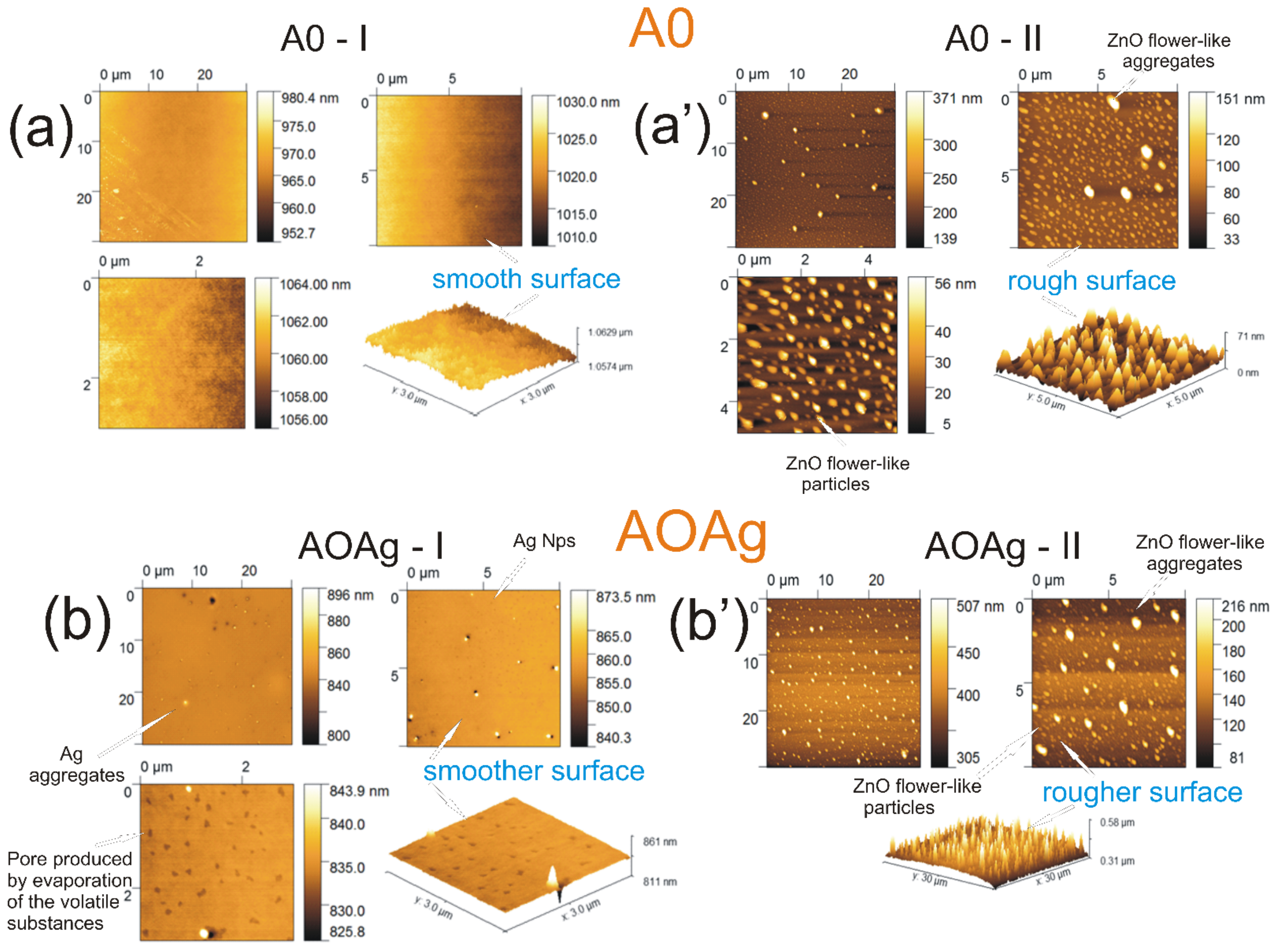

Coatings Free Full Text Novel Hydrophobic Nanostructured Antibacterial Coatings For Metallic Surface Protection

1 Polysaccharide Based Edible Films And Coatings Download Table

Coatings Free Full Text Novel Hydrophobic Nanostructured Antibacterial Coatings For Metallic Surface Protection

Fabrication Of Superhydrophobic Coatings With Edible Materials For Super Repelling Non Newtonian Liquid Foods Sciencedirect

Combining Edible Coatings Technology And Nanoencapsulation For Food Application A Brief Review With An Emphasis On Nanoliposomes Sciencedirect

Ijms Free Full Text Nanosystems In Edible Coatings A Novel Strategy For Food Preservation Html

Release Process In Edible Coatings Incorporated With Functionalized Download Scientific Diagram

Most Utilized Materials For Protein Based Edible Films And Coatings Download Scientific Diagram

Generalised Stepwise Diagram Of The Laboratory Development And Download Scientific Diagram

Durable Mixed Edible Wax Coating With Stretching Superhydrophobicity Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 D0ta10638k

Coatings Free Full Text Novel Hydrophobic Nanostructured Antibacterial Coatings For Metallic Surface Protection

Edible Films And Coatings With Pectin Springerlink

Coatings Free Full Text The Functionalization Of Nanostructures And Their Potential Applications In Edible Coatings Html

Comparison Of Moisture Wvp 20 C Ranges For Edible Coatings In Download Table

Edible Films And Coatings Major Challenges And Potential Applications In Food Packaging A Review Springerlink

Comparison Of Moisture Wvp 20 C Ranges For Edible Coatings In Download Table

Edible Films From Polysaccharides Semantic Scholar

0 Response to "edible hydrophobic coating"

Post a Comment